Why open Cell bonding?

WHY OPEN CELL BONDING?

The need for high performance, cost-effective manufacturing processes is more important than ever. Open cell bonding has emerged as a bonding technology, offering numerous benefits such as eliminating the display bezel and preventing air bubbles. Understanding how this process impacts cost yield and bond stack thickness can provide significant advantages for your design decisions. At Interelectronix, we excel in providing cutting-edge open cell bonding solutions tailored to meet the unique demands of design focused customers.

The Basics of Open Cell Bonding

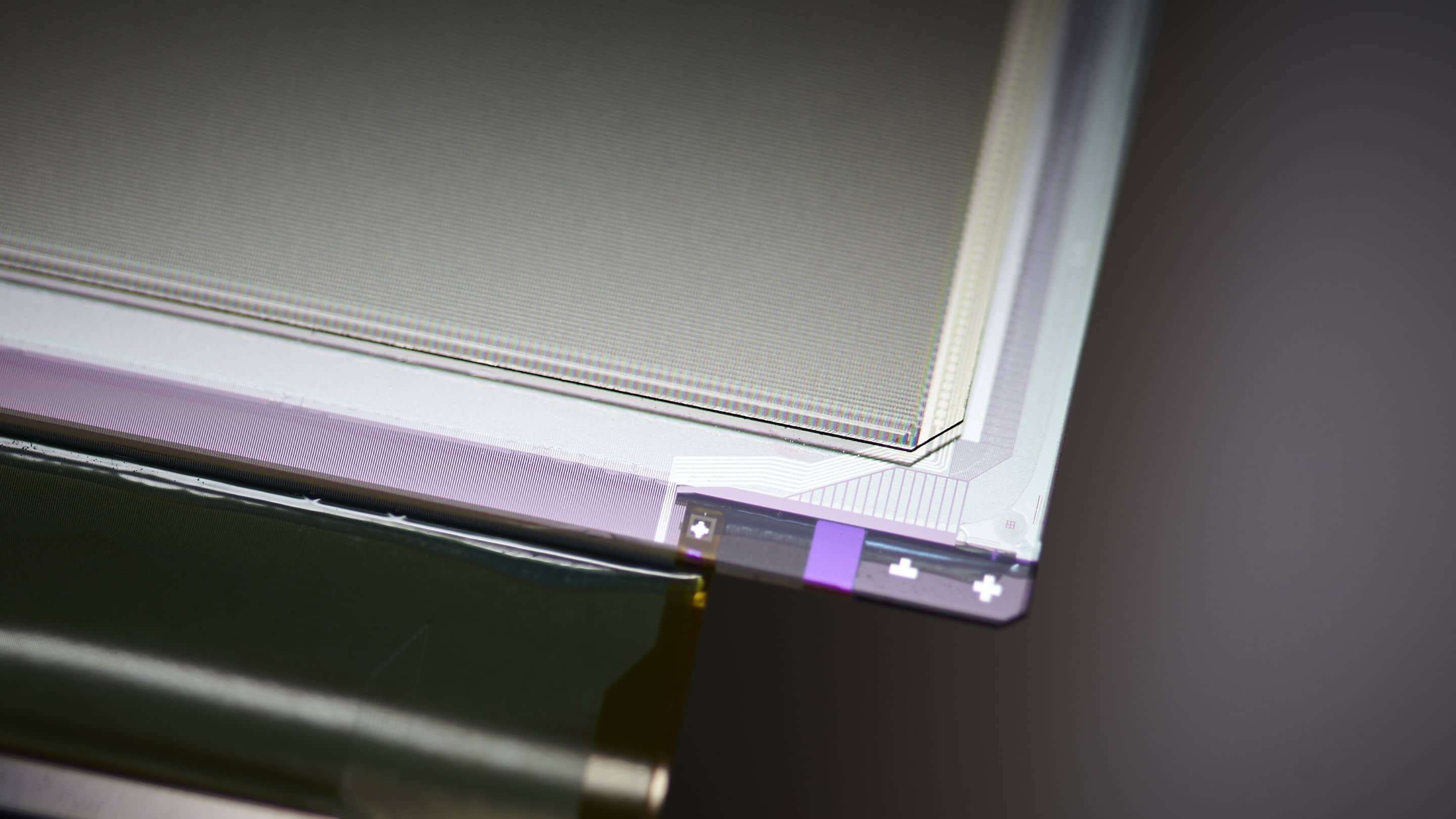

Open cell bonding is a technique where the liquid crystal display (LCD) cell is bonded directly to the backlight unit (BLU) without the traditional display bezel. This method eliminates gaps that can trap air and form bubbles, resulting in a seamless, high-quality display. By using a direct bonding approach, manufacturers can achieve thinner displays with improved optical performance, which is especially beneficial for modern, sleek device designs.

Better Optical Bonding Yields

One of the most significant advantages of open cell bonding is the elimination of the display bezel. Traditional displays often suffer from air gaps that can lead to the formation of air bubbles, compromising the visual quality and durability of the display. Open cell bonding removes this issue by directly bonding the LCD to the BLU, creating a seamless interface that enhances both the aesthetic and functional aspects of the display. This results in a more reliable and visually appealing product.

Application Versatility

Open cell bonding is versatile and can be applied to a wide range of display types and sizes. Whether you are developing small consumer devices or large industrial monitors, this bonding technique can be adapted to meet your specific needs. The flexibility of open cell bonding makes it an ideal choice for various industries, including automotive, medical, and consumer electronics. Interelectronix’s expertise in this area ensures that we can provide tailored solutions for any application.

Environmental Impact

In today’s market, the environmental impact of manufacturing processes is a growing concern. Open cell bonding contributes to sustainability by reducing material waste and energy consumption. The streamlined manufacturing process and the use of fewer components result in a smaller environmental footprint. At Interelectronix, we are committed to implementing eco-friendly practices and providing solutions that align with our clients’ sustainability goals.

Industry Expertise and Innovation

At Interelectronix, we pride ourselves on our industry expertise and commitment to innovation. Our deep understanding of open cell bonding technology allows us to provide cutting-edge solutions that meet the highest standards of quality and performance. We continually invest in research and development to stay at the forefront of display technology advancements, ensuring that our clients receive the most innovative and effective solutions available.

Enhanced Optical Performance

Open cell bonding significantly enhances the optical performance of displays. By eliminating the air gap and bezel, light transmission is improved, resulting in brighter, more vibrant images. This improvement is particularly beneficial for high-definition displays used in consumer electronics, automotive applications, and industrial equipment. Enhanced optical performance not only improves the user experience but also provides a competitive edge in the market.

Manufacturing Efficiency

The efficiency of the manufacturing process is another critical aspect of open cell bonding. By simplifying the assembly process and reducing the number of components, manufacturers can streamline production and reduce labor costs. This efficiency is achieved through the precise alignment and bonding techniques employed in open cell bonding, which minimize errors and increase throughput. At Interelectronix, we leverage advanced manufacturing practices to ensure efficient and cost-effective production.

Long-Term Durability

Durability is a key consideration for any display technology, and open cell bonding excels in this area. The strong bond between the LCD and BLU provides enhanced resistance to environmental factors such as temperature fluctuations and humidity. This increased durability translates to longer-lasting displays, which is a critical factor for applications in harsh environments. By choosing open cell bonding, you invest in a technology that offers both performance and longevity.

The Importance of Flat Substrates

Using flat substrates in open cell bonding is critical for achieving cost-effective yields. Flat substrates ensure a uniform bonding process, reducing the likelihood of defects and increasing production efficiency. This uniformity is essential for maintaining consistent quality across large production runs, which is a key factor in achieving high yields and cost savings. At Interelectronix, we prioritize the use of flat substrates to ensure the highest standards of manufacturing excellence.

Cost Yield and Bond Stack Thickness

In the context of open cell bonding, cost yield refers to the ratio of functional displays produced to the total number of displays manufactured. Achieving a high cost yield is essential for minimizing waste and maximizing profitability. Bond stack thickness, the total thickness of all layers in the bonded display, plays a crucial role in this process. Optimizing bond stack thickness helps in maintaining structural integrity while reducing material costs. By carefully controlling these variables, manufacturers can produce high-quality displays at a lower cost.

Information

The efficiency of the manufacturing process is another critical aspect of open cell bonding. By simplifying the assembly process and reducing the number of components, manufacturers can streamline production and reduce labor costs. This efficiency is achieved through the precise alignment and bonding techniques employed in open cell bonding, which minimize errors and increase throughput. At Interelectronix, we leverage advanced manufacturing practices to ensure efficient and cost-effective production.

The efficiency of the manufacturing process is another critical aspect of open cell bonding. By simplifying the assembly process and reducing the number of components, manufacturers can streamline production and reduce labor costs. This efficiency is achieved through the precise alignment and bonding techniques employed in open cell bonding, which minimize errors and increase throughput. At Interelectronix, we leverage advanced manufacturing practices to ensure efficient and cost-effective production.

Christian Kühn

Important

Open cell bonding is ideal for unique projects that emphasize a super slim design combined with an aluminum milled chassis. This technique ensures a sleek, high-quality finish, perfect for innovative designs where space and aesthetics are crucial. With a minimum project quantity of roughly 1,500 units per production, open cell bonding is the optimal choice for larger-scale, design-focused customers demanding a cutting-edge, slim profile touch monitor

Why Interelectronix

Choosing Interelectronix means partnering with a team dedicated to delivering high-quality, cost-effective display solutions. Our expertise in open cell bonding, combined with our commitment to customer satisfaction, ensures that you receive the best possible service and products. Contact us today to learn more about how our open cell bonding services can enhance your design vision and provide you with a competitive advantage in your industry. We look forward to helping you create stunning touch displays.

Call to action

Choosing Interelectronix means partnering with a team dedicated to delivering high-quality, cost-effective display solutions. Our expertise in open cell bonding, combined with our commitment to customer satisfaction, ensures that you receive the best possible service and products. Contact us today to learn more about how our open cell bonding services can enhance your design vision and provide you with a competitive advantage in your industry. We look forward to helping you create stunning touch displays.